You are here: Processes

PROCESSES AND PRODUCTION CONCEPTS AS REQUIRED

risomat covers the entire process of manufacturing stators and rotors

Thanks to its in-depth expertise, risomat masters the complete process chain for the production of stators and rotors.

Under the aspect of increasing automation and increasing quantities, the processes are constantly being further developed and optimized.

Process Steps

DESCRIPTION

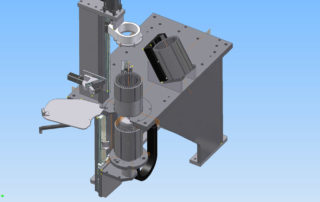

During the packetize process the individual insulated sheets are stacked to a stator and then connected to each other by various methods such as welding, gluing or clamping. When stacking appropriate measures must be taken to ensure the parallelism and eccentricity of the stator.

TYPES

Paketise Machines

vertical and horizontal types

manual or automatic stacking

APPLICATIONS

generators

big motors

servomotors

rotors

ADVANTAGES

technical design which guarantees a perfectly stacked stator package

fast tool change

flexible use and parameterizable

DESCRIPTION

During the isolating process isolating materials are used in different geometries accurately in the stator to isolate the coils against the stator high voltage resistant. Here, different insulating materials are used, which must be reliably introduced into the grooves.

TYPES

Insulating machines for the following insulation geometries

U- Shape

V- Shape

S- Shape

B- Shape

Y- Form

box type

APPLICATIONS

inside grooved stators

external rotor

all-purpose motors

rotors

hairpin stators

flat pack

ADVANTAGES

easy ergonomic operation

fast tool change

flexible applicable and parameterizable

constantly high embossing quality

isolation of loose stacked sheets

recording the process parameters

automatic reloading of the insulating material

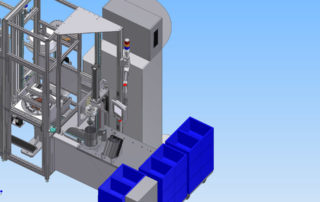

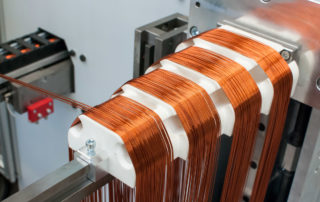

DESCRIPTION

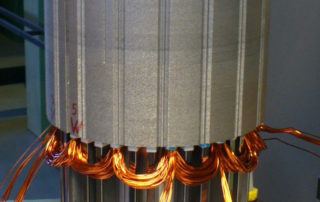

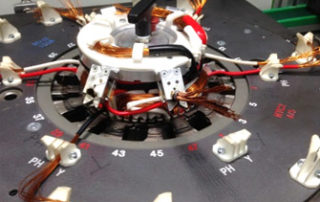

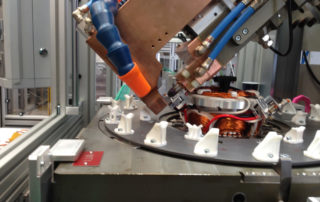

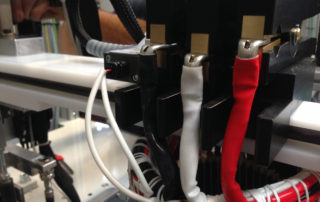

The flyer, linear or needle winding method is used for winding coils for stator and rotor windings. risomat masters all the aforementioned winding methods. Which method is used project-specifically, is decided together with the customer on the basis of technical and economic criteria’s.

TYPES

flyer winding (horizontal/vertical

linear winding

needle winding

APPLICATIONS

distributed windings

concentrated windings

pulled coil

rotor windings

windings of externally grooved stators

ADVANTAGES

mastery of all common winding methods

selection of the most suitable winding method for the corresponding application

flexible applicable and parameterizable

junction-free winding

automatic wire change

automatic tool change

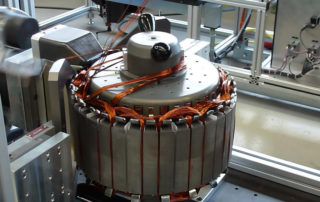

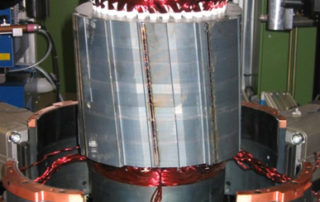

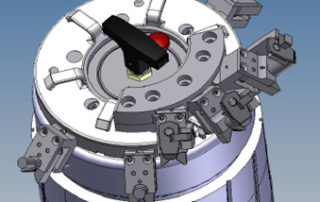

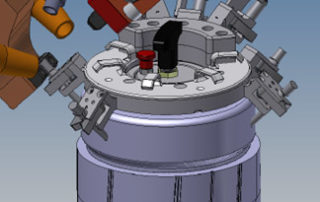

DESCRIPTION

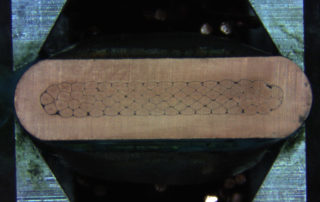

The introduction of the pre-wound coils into the stator slots is accomplished by means of the risomat pull-in technology. Here, the objective is to collect the coils without damage in the grooves and to achieve the highest possible degree of filling. When pulling in the grooves are additionally closed automatically by means of slot wedges.

TYPES

inserter (vertical)

inserter with integrated slot wedges machine

inserter combined with a winding machine

APPLICATIONS

single-layer and two-layer windings

pre-packaged stators

loose sheets

big motors

generators

pump motors (PVC insulated wires)

ADVANTAGES

high groove fill factor (> 50%)

short winding head

insert loose stacked sheets

mild insertion process by moving blades

easy quick changeover

automatic tool change

DESCRIPTION

The drawn-in coils must be shaped or compacted in the region of the winding head, so that the subsequent pulling-in process can be carried out, or after the preforming the bonding or after the final shaping the bandaging can be carried out.

TYPES

intermediate forming

pre forming

final forming

APPLICATIONS

traction motors

pump motors (PVC insulated wires)

ADVANTAGES

high forming quality

fast tool change

flexible applicable and parameterizable

easy process-safe forming concept

automatic tool change

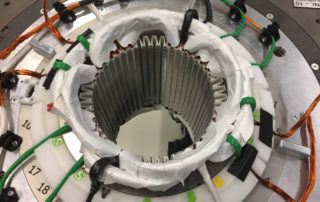

DESCRIPTION

In stators for generators and PSM machines, the sheets are skewed, so that the voltage or torque ripple can be kept as small as possible. risomat has developed a process whereby the stators can be set and welded after all coils are inserted.

TYPES

skewing-welding (horizontal)

forming-skewing-welding (vertical)

APPLICATIONS

generators

stators for PSM machines

ADVANTAGES

high flexibility due to programmability of all setting parameters

fast tool change

exact rectilinear setting of the stator laminations

exact concentricity of the stator bore

integration of several machining processes

DESCRIPTION

The coil lead, which is laid on the winding head, must be insulated by means of insulating hoses against high-voltage and partial discharge. risomat has enormously optimized and streamlined this manual operation with the help of an ergonomic manual workstation, as well as a wiring template and a tube dispenser. The isolated leads are stored and fixed on a patented stator workpiece carrier.

risomat is currently working on the complete automation of the sliding of the insulating hoses.

TYPES

manual workstation

stator workpiece carrier

tube dispenser

APPLICATIONS

stators of all pole numbers

ADVANTAGES

ergonomic hand or standing workstation

storage and fixation of the isolated discharge on the stator workpiece carrier

storage and fixation of the isolated connections on the stator workpiece carrier

working on the complete automation of this process

DESCRIPTION

The coils of the individual phases must be insulated from each other in the winding head against high-voltage and partial discharge. risomat has enormously optimized this manual activity with the help of an ergonomic manual workstation. risomat is currently working on the complete automation for introducing the phase separators.

TYPES

manual workstation

dispenser of phase separators

APPLICATIONS

stators of all pole numbers

single and two layer winding

ADVANTAGES

ergonomic hand or standing workstation

working on the complete automation of this process

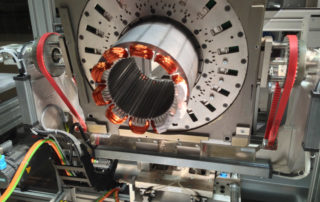

DESCRIPTION

The coil leads, which are stored on the stator workpiece carrier, must be connected in star or delta connection. In order to make this process reproducible, risomat has enormously optimized and streamlined a method based on the use of a wiring template. risomat is currently working on the complete automation of the interconnection.

TYPES

manual workstation

wiring template

APPLICATIONS

stators of all pole numbers

single and two layer winding

ADVANTAGES

ergonomic hand or standing workstation

reproduceable and exact installation of the coil leads by using a wiring template

automatic contacting with the support of the fixed leads in the wiring template

working on the complete automation of this process

DESCRIPTION

After interconnection, the coil terminals are contacted, preferably by the hot-crimping method.

TYPES

automatic hot-crimping machine

APPLICATIONS

stators of all pole numbers

single and two layer winding

ADVANTAGES

fully automatic process

recording of all relevant process parameters

automatic electrode measurement

DESCRIPTION

The coils in the winding head on the switching and non-switching side are laced with a cord. This ensures that, on the one hand, the interconnected leads abut compactly on the winding head and, on the other hand, no loose wires protrude for impregnation.

TYPES

lacing machinery – single

lacing machinery – double

APPLICATIONS

stators of all pole numbers

single and two layer winding

ADVANTAGES

high flexibility through programmability of all setting parameters

run control based on an electronic cam disc

fast tool change

automatic package length measurement

pull regulation of the lacing cord

automatic fastening

DESCRIPTION

After lacing and final forming, when the stator is prepared for impregnation, the electrical testing of the incorporated winding and insulation system is performed. The following measurements are used: resistance, inductance, impulse voltage, partial discharge, high voltage, insulation resistance and rotating field.

TYPES

manual workstation

automatic measurement system

APPLICATIONS

stators of all pole numbers

single and two layer winding

ADVANTAGES

integration in the production process

automatic stator handling and contacting

automatic test procedure

automatic evaluation of measured values and archiving